Wood Shaper Versus Router

Larger shaper cutters and oversize router bits like panel raisers require slower speeds while small router bits need higher speeds to do the job.

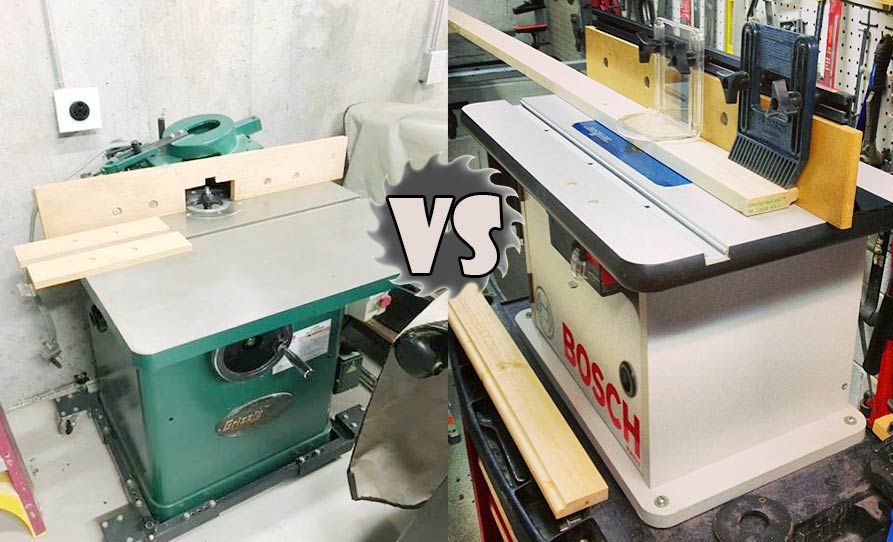

Wood shaper versus router. Router bits are way smaller than shaper bits in diameter. Wood shaper vs router uses there is very less that you can do with a shaper and not with a router. There s very little a shaper can do that you can t duplicate with a router table. This is often done by moving a belt on the drive pulleys.

The wood shaper or spindle molder cutter spurs a longer path but a router table can be used for shorter tracks. You can however use a router as a shaper but you cannot use a shaper as a router. One way to look at the difference is that relatively speaking universal motors provide high rpm and low power and induction motors provide low rpm and high power. Heavy machining a shaper is designed for larger volume work while a router is a hand tool for lighter duty work.

Shapers like most table saws jointers and stationary planers run on induction motors. The cutting speed you want is dependent on the diameter of the cutter or bit. Wood shapers tool can make deep and long cuts on the wood which is not the case with routers. Shapers are used more often in industrial woodworking shops and i do almost all my machining of wood with a really good well built router table.

The results of using a shaper are smoother than that of a router. When we feel that the tool is being pushed to its limit it becomes not only bad for the final product but also a danger. Shaper speed just as a router needs to be slowed to perhaps 10 000 rpm for larger router bits a shaper needs to be slowed even farther for the larger shaper cutters 7 000 rpm is common for large shaper cutters but even slower may be needed for very large cutters. A wood shaper is quite expensive but router bitsrequire little expense to use.

Even though the router bits are smaller they make far more revolutions per second rpm than a shaper does. One option for those looking as a wood shaper vs router table is the ability to make reverse cuts. That gives you far more wood contact and a cleaner cut than you d get with a shaper. Shapers typically run at 7 000 to 10 000 rpm while routers typically run at 22 000 to 25 000 rpm.

Rick white the short answer is no. Routers like shop vacuums and bench top planers run on a universal motor. Therefore the precision work and jobs that require repeatability need shaper as their equipment.